Silicone Stone Molds Making

Professionals in concrete casting worldwide recognize CREKEM liquid rubber products as the gold standard for creating durable rubber molds. These molds offer the abrasion resistance and tear strength necessary to maintain efficient production. Casting concrete into molds made with CREKEM rubber ensures flawless replicas of any original, every single time! Craft your own concrete molds, forms, textures, and stamping mats with ease.

Specification of Liquid Rubber Mateirals for Stone Silicone Mold

Molding Silicone For Stone Silicone Mold

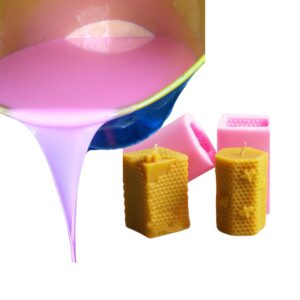

Molding silicone is a commen liquid rubber material for creating durable and highly detailed stone silicone mold. This type of silicone is specifically formulated to capture the fine details of stone textures, making it ideal for producing replicas, decorative elements, and architectural features. Molding silicone Rubber is known for its flexibility, strength, and ability to produce high-quality results, even after multiple uses. Whether you are a professional stone mold maker or a DIY stone molds hobbyist, using liquid silicone for stone molds ensures that your molds are resilient and capable of producing consistent, high-quality stone casts.

Molding Silicone For Stone Silicone Mold Application

The application of molding silicone for stone molds is straightforward and versatile. It is commonly used in the creation of architectural elements, garden ornaments, sculptures, and other decorative stone products. The silicone rubber’s ability to replicate intricate details makes it perfect for capturing the natural textures of stone. When preparing a mold, ensure that the surface of the stone is clean and free of debris. The silicone is then mixed and poured over the stone surface, where it cures to form a flexible, durable mold. This mold can then be used repeatedly to produce multiple stone replicas

How to color a stone silicone mold ?

Choose Pigment: Use silicone-specific pigments compatible with your mold material.

Mix Pigment: Add a few drops of pigment to your silicone rubber and mix thoroughly until you reach the desired color.

Test: Test the color on a small sample to ensure it’s what you want.

Pour and Cure: Pour the colored silicone into your mold and let it cure as directed.

Optional: Apply silicone-based pigments for additional surface details if desired.

Datasheet of Molding Silicone For Stone Silicone Mold

| Properties | Tin Silicone | Platinum Silicone | Polyurethane |

|---|---|---|---|

| Type | RTV-2 | RTV-2 | Polyester |

| Hardness ( shore A ) | 20-40 A | 30-40 A | 40-50 A |

| Tensile Strength | 3-5 MPA | 3-5 MPA | 25-35 MPA |

| Shrinkage | 0.3~0.5% | 0.1% | 0.1% |

| Melting Point (°C) | -50 °C to 230 °C | -50 °C to 230 °C | -50 °C to 80 °C |

| Abrasion Resistance | Poor | Poor | Excellent |

| Heat Resistance | Good | Excellent | Poor |

| Economical | Low Cost | High Cost | Low Cost |

Develop & Custom Molding Silicone Rubber for Silicone Stone Molds

We prioritize our customers’ needs and continually innovate based on our extensive experience and expertise. This enables us to expand our product range to meet the diverse requirements of our clients.

Our facilities are equipped to produce high-quality molding silicone rubber, ideal for creating stone silicone mold. We offer a range of products with varying hardness from 20A to 40A, available in different shapes, sizes, and colors. Additionally, we can customize silicone rubber products based on your requires to suit your specific application needs.

- Most of our standard silicone rubber are available for fast delivery.

- If you require custom molding silicone rubber for stone mold making, contact us today for more information. We are here to assist you.

Related Products