Features:

1) Easy to operate, mixing ratio 100 A : 10 B or 1A:1B

2) Hardness from 30 shore A to 50 shore A

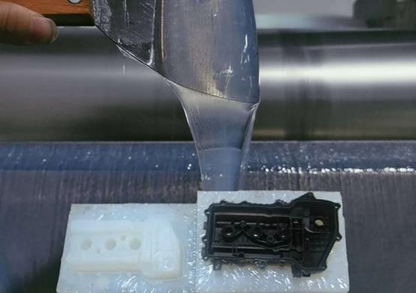

3) Amazing fluidity , not oily

4) Exquisite reproduction of detailed patterns

5) Easy de-molding, Good Flexibility

6) Excellent tension and tear strength

7) No Shrinkage, no deformation

8) Platinum-based, food-grade silicone, environmental friendly

Package:

Small Packaging : 200g/bottle, 500g/bottle and 1kg/drum, 5kgs/drum.

General packaging : 20kgs/drum, 25kgs/drum, 200kgs/drum, 1000kgs/drum.

Shelf life and transportation:

1. Twelve(12) months when stored at 25C in tightly closed original packages.

2. Read the material safety data sheet(MSDS), Datasheet before use.

3. This kind of product is non-dangerous product, which could be transported as general chemicals.